Century Sparks provides a comprehensive array of synthetic diamond powder in the micron and sub-micron size range. Micron diamond powders are widely used for the finishing of hard materials with demanding specifications for surface quality and dimensional accuracy. For effective use this powder should be mixed into a polishing compound or slurry with some type of a carrier.

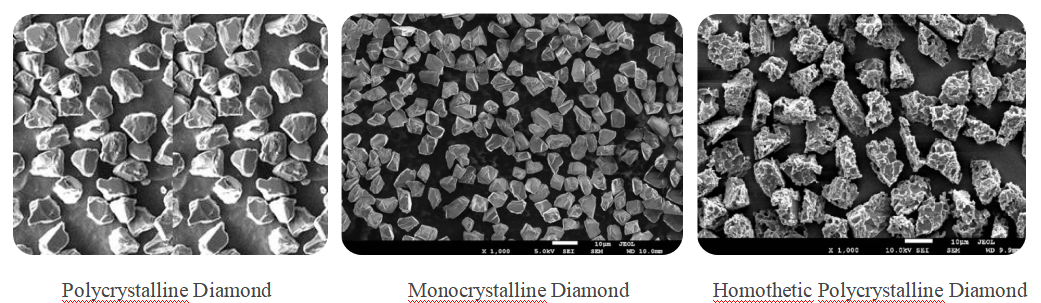

Polycrystalline Diamond Powder(PDP)

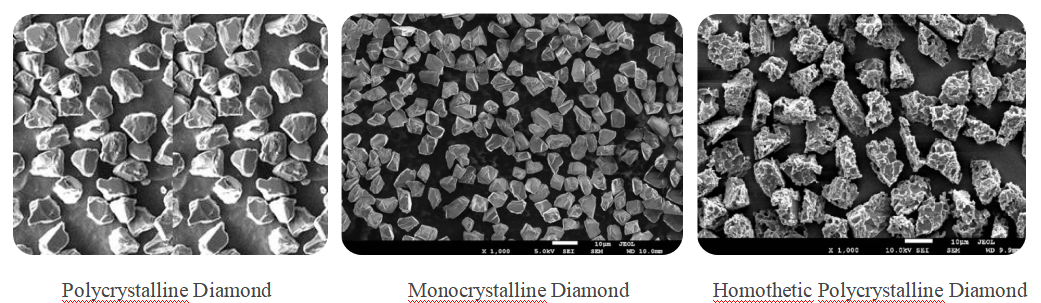

Polycrystalline diamond powder is formed by explosion method, leading to an aggregate structure without cleavage planes. The resulting high toughness of polycrystalline diamond tolerates three times higher operating pressures than monocrystalline diamond. Its micro-structured, rough particle surface provides numerous contact points between diamond particles and the workpiece. These characters allow for significantly higher material removal rates compared to other diamond types. Typical applications of polycrystalline diamond powder are high-performance lapping and polishing processes.

|

Physical Property

|

State

|

Detection Method

|

|

Appearance

|

Grey Powder

|

|

|

Shape

|

Razor-edged corners

|

SEM

|

|

Crystal Form

|

Polycrystalline

|

X-rays Diffraction

|

|

Particle Size

|

0.1-10um (Raw Powders)

|

Ldsa

|

|

Dispersion Range

|

0-1,0-2,1-3,2-4,2-5,3-6,4-8,5-10um

|

Ldsa

|

|

Chemical Composition

|

C:>99%

|

Elemental Analysis

|

Monocrystalline Diamond Powder(MDP)

Monocrystalline diamond powder is produced by high-pressure and high-temperature method. The diamond particles feature an oriented crystal structure with parallel-running cleavage planes. For diamond tools, particle fracturing provides a self-sharpening mechanism and thus increases tool life. It is popular choice for precision grinding, lapping and polishing of various materials.

|

Dimension

|

D10(um)

|

D50(um)

|

D95(um)

|

D100(um)

|

|

D20-30

|

>15.00

|

18.80-21.60

|

<30.000

|

<52.330

|

|

D10-20

|

>10.00

|

13.00-14.00

|

<22.500

|

<37.000

|

|

D8-16

|

>6.70

|

8.50-10.00

|

<15.500

|

<31.000

|

|

D6-12

|

>5.60

|

7.30-7.80

|

<12.000

|

<22.000

|

|

D5-10

|

>4.20

|

5.50-6.04

|

<10.000

|

<15.560

|

|

D4-8

|

>3.69

|

4.70-5.23

|

<8.500

|

<13.080

|

|

D4-6

|

>2.75

|

3.50-3.90

|

<6.000

|

<10.000

|

|

D2-5

|

>2.35

|

3.15-3.25

|

<5.500

|

<8.482

|

|

D2-4

|

>1.73

|

2.40-2.65

|

<4.500

|

<7.778

|

|

D1.5-3

|

>1.16

|

1.60-1.74

|

<3.500

|

<5.044

|

|

D1-2

|

>1.05

|

1.40-1.50

|

<2.700

|

<3.889

|

|

D0-2

|

>0.75

|

0.91-1.04

|

<1.860

|

<2.522

|

|

D0-1

|

>0.53

|

0.60-0.70

|

<0.980

|

<1.500

|

|

D0-0.5

|

>0.32

|

0.45-0.55

|

<0.880

|

<1.300

|

Homothetic Polycrystalline Diamond Powder(HPDP)

The surface characteristics of Century Sparks HPDP deliver remarkable material removal rate with the added benefit of good surface finish. The HPDP comes in the form of powder or slurry and is ideally suitable for LED and semiconductor materials (i.e. sapphire, SiC, silicon), metallographic applications and fine finishing. Due to the distinctive micro-faceted diamond surface that provides small cutting points to drastically reduce the surface roughness of the workpiece.

|

Specification

|

D10(μm)

|

D50(μm)

|

D90(μm)

|

|

2-4

|

≥1.90

|

2.7-2.9

|

≤4.26

|

|

2-5

|

≥2.22

|

3.1-3.3

|

≤4.62

|

|

3-5

|

≥2.55

|

3.6-3.9

|

≤5.46

|

|

3-6

|

≥2.92

|

3.9-4.3

|

≤6.02

|

|

4-6

|

≥3.36

|

4.5-5.0

|

≤6.90

|

|

4-8

|

≥4.35

|

5.8-6.1

|

≤8.54

|

|

5-9

|

≥4.57

|

6.1-6.4

|

≤8.96

|

|

5-10

|

≥4.97

|

6.5-7.4

|

≤10.35

|

|

8-12

|

≥6.75

|

9.0-10.5

|

≤14.60

|

|

12-22

|

≥11.35

|

15-17

|

≤23.30

|

|

15-25

|

≥13.30

|

17.5-19.3

|

≤26.52

|

|

20-30

|

≥15.20

|

20-23

|

≤31.70

|

|

25-35

|

≥17.45

|

23-26

|

≤36.00

|

|

30-40

|

≥24.25

|

32-36

|

≤49.90

|

Applications: