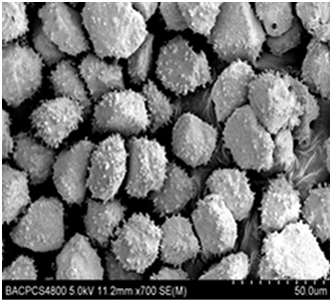

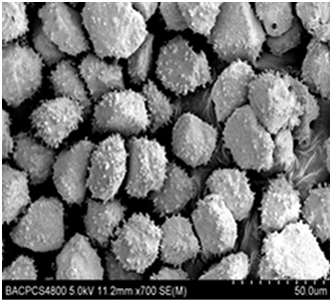

Century Sparks has solved the adhesion and leakage problem in the coating process, and carried out the electroplating and chemicalnickelage coating, compositenickel-plating, and tetanizing on a series of superhard material products.Customers can also request different weight gain and processing services.

Specifications:

|

|

Flat coaing

|

Splinter coating

|

|

Abrasive

|

Diamond

|

Diamond

|

|

Weight gain(%)

|

30、55

|

30、55

|

|

Particle Size/μm

|

According to customer needs to provide the appropriate size model

|

|

Nickel Weight Grain

|

Standard weight gain is 55% and 30%

|

|

In addition to the above specifications,Roll products can be customized according to customers’ requirements.

|

Features

1、 1、Applying advanced plating technique to achieve fine surface and high removal rate.

2、 2、Large surface roughness and high bonding agent

3、Best solution to longer life and better heat dissipation

4、No omissions and adhesions

5、Good thermal and chemical stability.

Field of application

electroplating diamond fretsaw;resin diamond fretsaw; resin bond diamond abrasive/grinding wheel; Semiconductor processing diamond abrasive/grinding wheel ;diamond based tools;electroplating diamond grinding heads;high strength nickel bonding ;long-life grinding/abrasive wheel;

Particle size of electroplate:50/60#~325/400#

Particle size of chemical plating:3um~200um

Field of application:

|

|

|

|

|

Diamond Wire Saw

|

Electroplated Diamond Grinding Head

|

Electroplated Diamond Grinding Wheel

|

Grinding Disc

|