Century Sparks Diamond lapping film is coated with precisely graded minerals on the high strength polyester backing to provide a uniform, consistent finish, enable abrasives oriented and even distribution, result in higher efficiency of grinding and better polishing effect. The minerals include diamond, aluminum oxide, silicon carbide, silicon oxide, cerium oxide and so on, which is suitable for grinding and polishing multiple of hardness materials and other materials.

Main specification

|

Material

|

Diamond,AluminumOxide, SiliconCarbide,CeriumOxide

|

|

Grit size /um

|

80

|

60

|

45

|

30

|

15

|

9

|

6

|

3

|

1

|

0.5

|

|

Backing thickness

|

125μm(5mil)75μm(3mil)

|

|

Product specification

|

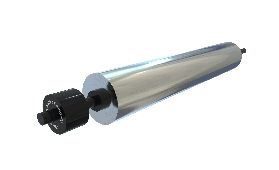

101.6mm×15m,101.6mm×45m

Φ127mm、 Φ203mm(8inch)、114mm*114mm(4.5inch)、140mm*140mm,152mm*152mm(6inch)、

228mm*228mm(9inch),228mm*280mm

special specifications can be customized,back can be with glue and velvet

|

Note:Provide OEM and customized for users

Features:

•Good grinding efficiency for surface’s high-resolution with different precision demand;

•It not only has the characteristics of high grinding force of fixed abrasive such as grinding wheel, but also can achieve the polishing accuracy of free abrasive such as grinding fluid;

•It has good strength and flexibility, and can achieve ideal surface polishing effect;

•Consistent finishing performance;

•High durability and cost reduction;

•Available for dry polishing and wet polishing.

Application:

Polishing and polishing of all kinds of optical fiber connectors and optical fiber devices in the optical communication industry;

Precision polishing of optical glass, crystal and LCD substrate;

Magnetic head, computer hard disk surface grinding polishing;

Surface polishing and repair of car paintwork and high-grade furniture;

Grinding and polishing in metallographic analysis of metals and alloys, ceramics, glass, etc…